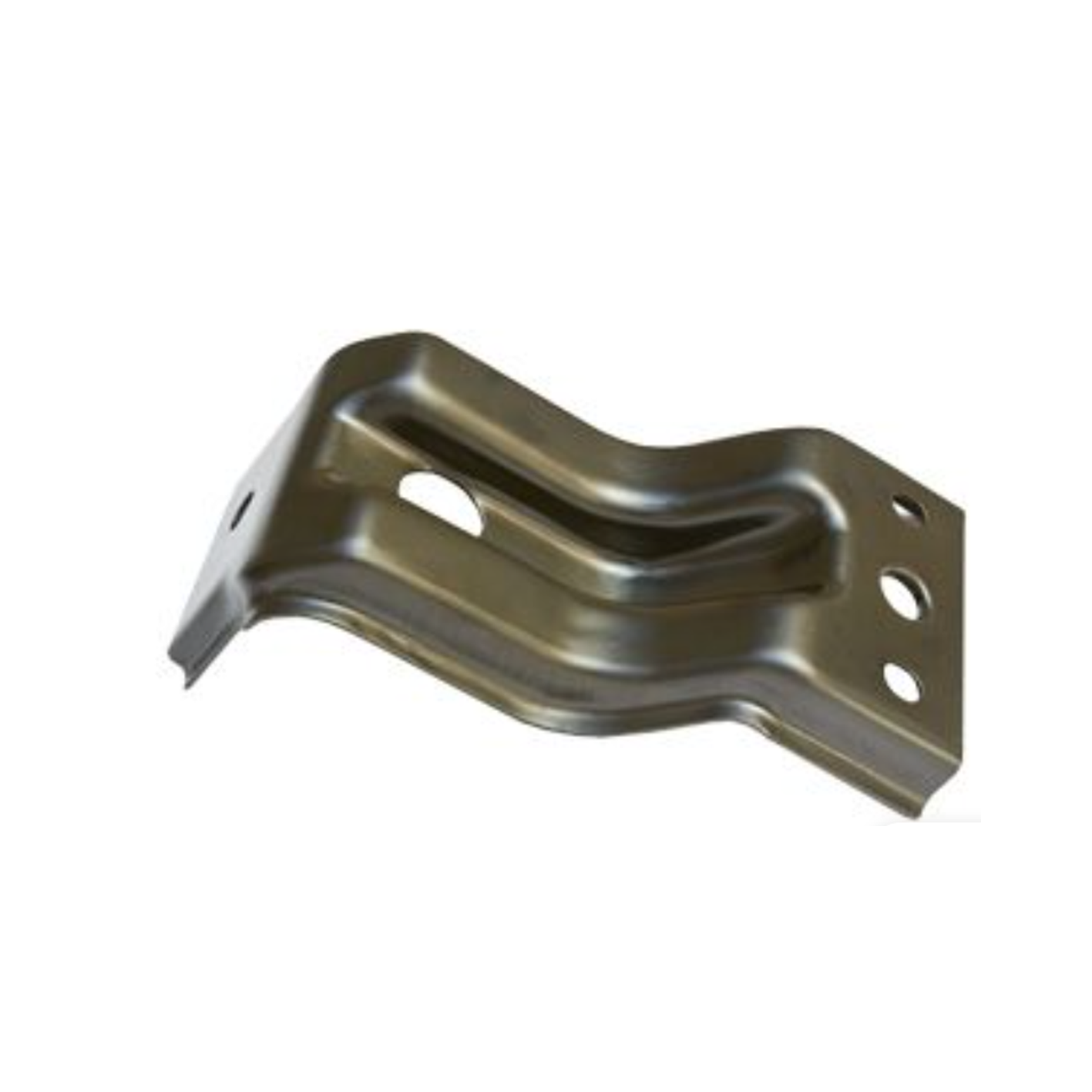

Hoʻopilikino ʻia nā huahana hoʻoheheʻe ʻia i nā lau metala

wehewehe

| ʻAno Huahana | huahana hoʻopilikino | |||||||||||

| Hana Hookahi | ʻO ka hoʻomohala ʻana a me ka hoʻolālā-hoʻouna ʻana i nā laʻana-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Kaʻina hana | hehi, kulou, kiʻi hohonu, hana ʻia me ka pepa, wili, ʻoki laser etc. | |||||||||||

| Nā mea waiwai | kalapona kila, stainless steel, aluminika, keleawe, galvanized kila etc. | |||||||||||

| Anana | e like me nā kaha kiʻi a ka mea kūʻai aku. | |||||||||||

| Hoʻopau | E kāpīpī i ka pena, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Wahi noi | ʻO nā ʻāpana kaʻa, nā ʻāpana mīkini mahiʻai, nā ʻāpana mīkini ʻenekinia, nā ʻāpana ʻenekinia kūkulu, nā lako kīhāpai, nā ʻāpana mīkini pili i ke kaiapuni, nā ʻāpana moku, nā ʻāpana mokulele, nā paipu paipu, nā ʻāpana hāmeʻa, nā ʻāpana pāʻani, nā ʻāpana uila, etc. | |||||||||||

Pono

1. Ma mua o 10 makahikio ka ike kalepa ma na aina e.

2. Hoolakolawelawe hoʻokahimai ka hoʻolālā mold a hiki i ka lawe ʻana i nā huahana.

3. ʻO ka manawa hāʻawi wikiwiki, e pili ana30-40 mau lā. Loaʻa i loko o hoʻokahi pule.

4. ʻO ka hoʻokele maikaʻi a me ke kaʻina hana (ISOmea hana i hōʻoia ʻia a me ka hale hana).

5. ʻOi aku nā kumukūʻai kūpono.

6. ʻOihana, loaʻa i kā mākou hale hanaʻoi aku ma mua o 10makahiki o ka mōʻaukala ma ke kahua o ka metala stamping sheet metala.

Hoʻoponopono maikaʻi

Vickers mea paʻakikī.

Mea hoʻohana ʻikena.

Mea kani spectrograph.

ʻEkolu mea kani hoʻohui.

Kii Hoouna

Kaʻina Hana Hana

01. Mold design

02. Hoʻoheheʻe ʻia

03. ʻO ka hana ʻoki uea

04. Mold wela lapaʻau

05. Hui poni

06. Mold debugging

07. Ka hoopau ana

08. electroplating

09. Ho'āʻo Huahana

10. Pūʻolo

Hoʻolauna i nā mea elevator

ʻO nā mea metala maʻamau i hoʻohana ʻia i loko o nā mea hoʻokiʻekiʻe ʻo ia ka nui o ke kila kila, ke kila hoʻoheheʻe ʻia, ke kila hana kalapona, ke alumini alumini, ke keleawe, nā ʻaoʻao anu, nā ʻaoʻao wela, a me nā mea ʻē aʻe.

Ke kila kila: ʻAʻole hiki ke hoʻomaʻemaʻe ʻia. Hoʻohana pinepine ʻia i nā lau puka elevator, nā ʻaoʻao ʻaoʻao puka a me nā ʻāpana ʻē aʻe.

Alloy structural steel a carbon structural steel: Loaʻa iā lākou ka ikaika kiʻekiʻe a me ka paʻakikī a hoʻohana ʻia e kū i ka ukana o nā elevators. Hoʻohana pinepine ʻia lākou i nā ʻāpana puka elevator, nā papa puka a me nā ʻāpana ʻē aʻe.

ʻO ka alumini alumini he māmā ke kaumaha, ka ikaika kiʻekiʻe a me ka plasticity maikaʻi, a hoʻohana ʻia i nā kaupaku a me nā pā pā.

Copper: Hoʻohana ʻia ia i nā ʻāpana kaapuni a me nā ʻāpana o nā mea hoʻokiʻekiʻe a loaʻa iā ia nā ʻano o ka anti-oxidation, ke kani a me ka wela.

Nā kiʻi kiʻekiʻe kiʻekiʻe a me nā ʻaoʻao wela: He ikaika kiʻekiʻe ko lākou, ʻaʻahu kūʻē, kūʻē i ka deformation, ikaika kiʻekiʻe a paʻakikī hoʻi, a hoʻohana ʻia i ka hana ʻana i nā ala alakaʻi alakaʻi.

ʻO ka hoʻohana ʻana i nā mea metala like ʻole e like me ke kumu, ke kumu hoʻohālike a me ka hōʻailona o ka elevator. Ke koho ʻana i nā mea metala kūpono, pono ʻoe e noʻonoʻo e hōʻoia i ka hana palekana o ka elevator.

No ke aha e koho ai iā mākou

1. Expert ka hana ʻana i nā ʻāpana metala a me nā ʻāpana stamping metala no nā makahiki he ʻumi.

2. ʻO kahi papa kiʻekiʻe o ka hana ʻana kahi mea a mākou e nānā nui ai.

3. Loaʻa ke kākoʻo koʻikoʻi a puni ka manawa.

4. I loko o hoʻokahi mahina, hiki wawe ka lawe ʻana.

5. He hui ʻenehana ikaika e kākoʻo a kākoʻo i ka noiʻi a me ka hoʻomohala ʻana.

6. Manaʻo i ka hui pū ʻana o OEM.

Loaʻa iā mākou nā manaʻo maikaʻi mai kā mākou mea kūʻai aku a liʻiliʻi loa nā hoʻopiʻi.

8. Loaʻa i kēlā me kēia huahana nā waiwai mechanical maikaʻi a me ke ola kūpono.

9. He kumu kūʻai hoʻokūkū kūpono.